- Home

- Machinery

Machinery

For more than two decades, Shunzhan Machine has been dedicated to the manufacturing of fiber processing machines. Our equipment offers the advantages of reliability, high efficiency, and safety.

-

- Fiber Opening The fiber opening machines are designed for opening and loosening fibers for the purpose of filling pillows and cushions.

-

- Fiber Filling Machine The fiber filling machine is designed to fill various products with fiber, such as stuffed animals, pillows, backrests, seat cushions, and much more.

-

- Ball Fiber Machine The ball fiber machine is specialized equipment designed to turn raw materials into balls of fiber without damaging the fiber.

-

- Shredder for Foam The shredder for foam can shred the sponge (including offcut materials) into small pieces and granules of Φ3mm-Φ50mm.

-

- Vacuum Packaging Press The shredder for foam can shred the sponge (including offcut materials) into small pieces and granules of Φ3mm-Φ50mm.

-

-

High Production Rate

Our machines come equipped with a large roller and five small rollers. The gaps of the rollers are specially configured to ensure an opening rate of the fiber up to 98%. The production rate of our equipment is 50% higher than that of traditional single roller machines.

-

-

Safety

We pay great attention to the safety performance of each of our machines. All the circuitry in our machinery has leakage protection and each motor has overload protection features. It will automatically cut off the power when short circuit or material blockage occurs. Each door of our machine has a protection switch to ensure the safety of the operator.

-

-

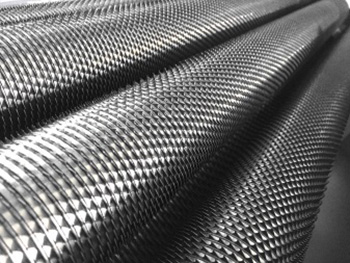

Durability

The large rollers undergo dynamic balance processing, ensuring they can run without noise and vibration, extending their service life. The sprockets and gears undergo heat treatment, increasing their hardness and durability. The sheet metal of the machine features a baking finish that ensures excellent rust resistance. The service life of the machine is about 5-10.

-

-

Energy Saving

The motors of our machine are controlled by frequency converter, so they are durable and energy-saving. The output of fibers feature a special design to save the air supplied by air compressor to avoid the frequent starting of the air compressor, minimizing energy consumption.

-

-

Good effect

The large roller runs at a slow speed of 1400 rpm/min to prevent damaging the fiber, while improving its looseness. The equipment is designed to avoid wiping out silicone oils on the fiber, leaving them nice and smooth.

-

-

Convenience

Every machine comes with a convenient cleanup function. When material blockage occurs, you can open the door and engage the cleanup function to clear the blockage.

-

-

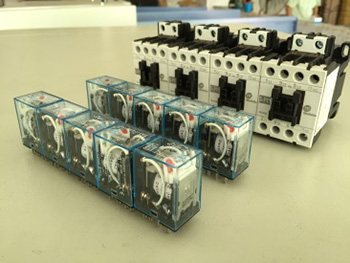

Stability

We use high-quality electrical components. PLC controllers are made by Mitsubishi, ensuring machine stability.

-

-

Automation

Our machine can realize automatic material feeding to save labor costs according to your requirements.